How to use AI for detecting product defects

AI visual inspection is an emerging technology in manufacturing. The blog discusses how manufacturers can use AI in defect detection & visual inspection with accuracy – intended for CIOs, IT directors, and data experts of the same industry.

Thulasi

Jan 5, 2026 |

9 mins

What is AI visual inspection for defect detection in manufacturing?

Manual defect detection is a meticulous process and even with extreme vigilance, a few defected pieces might slip in. If you are looking for how to improve quality control in manufacturing, that’s where AI-based defect detection comes in. This advanced technique can help a busy production plant find out defected pieces with high speed, consistency, and accuracy.

AI-powered defect detection uses vision technology, IoT, and AI-based monitoring systems to identify flaws, structural defects, or packaging issues while manufacturing, even the minute ones that gets missed during human inspection.

How AI defect detection works?

There are three major components in every AI-based defect monitoring system.

IoT, sensor, and vision technology: The first line of defect monitoring which uses high resolution cameras and sensors to capture the images of manufactured products in all angles, as they move across the assembly line.

AI, machine learning, and deep learning: machine learning is used for pattern recognition, which does a surface-level inspection to identify defective products. Any structural anomalies can be identified here whether the algorithm is trained for it or not.

Deep learning is to identify defects in complex shapes, structures, or patterns. Example: internal flaws, structural weakness, etc. Advanced algorithms like CNN are used here, which is trained with various images and videos, x records, or ultrasound results of a perfect and defected product.

Automated monitoring: Alert systems will flag defected items instantly, based on the AI system’s feedback. One can also set up automated rejection systems to knock off products for further testing based on the final defect percentage.

Over time, the AI visual inspection tool improves its efficiency learning from recurring issues, feedback, and defect patterns.

In short, AI visual inspection and defect detection works by using vision technology, ultrasound, and x ray systems to capture product images, x ray, and other analysis files. An AI model is used to read these signals and analyze surface level and in-depth defects and structural weaknesses. With automated monitoring, triggers raise when a defective piece pass through, helping humans with accurate and simplified inspection.

How AI helps across industries for detecting product defects?

AI product defect identification has use cases across industries. AI for detecting product defects is used in logistics, manufacturing, retail, pharma, CPG, FMCG, etc.

Logistics

Logistics industries often come across situations like torn packaging, dented, or damaged products that they cannot ship/send. There are also other nuanced issues where AI can strengthen defect inspection and minimize work.

Product damage due to temperature control, especially perishable goods.

Misplaced items or items loaded in wrong trucks

Tampered products, broken seals, and packaging and labelling errors.

Packaging errors, tampering, or damaged products being packed can be checked using cameras or x-ray vision and AI-visual inspection can detect these damaged packages and alert the team before it reaches the shipment area. This way, logistics and warehousing units can prevent costly claims and negative customer reviews without involving too much labor.

Manufacturing

Even with automated assembly lines and end-to-end quality control, manufacturing units can produce products with structural or internal defects. Convoluted Neural Networks-based solutions can help the industry analyze and spot all types of possible defects. Similarly, there is predictive analytics which helps manufacturers predict and fix flaws in machinery ahead. With intuitive applications like predictive analytics and AI-defect detection, manufacturing industry could save a lot of money and time spent on finding and fixing defects.

Retail

Retail could benefit from AI-visual fault detection in both warehouse and in-store operations. Being in customer-facing field, it’s crucial for them not to let damaged goods reach their customers, but manual checking alone could be painstakingly chaotic. That’s where AI visual inspection for defect detection comes in place for both retail and eCommerce companies to detect misplaced items, damages, and label errors, helping the quality team minimize and streamline their work, improving inventory accuracy, and enhancing customer shopping experience.

Pharmaceutical

Pharma industry needs to ensure safety, quality, and compliance. Even a small incorrect dosage or packaging error could become detrimental, mandating heavy and multiple levels of quality-checks. Pharma quality control could become simpler and more accurate with AI’s help, simplifying the detection of incorrect dosages, contamination, broken seals, expiration & other info accuracy, safety seal check, and other microscopic defects. Hence, even if there are machinery faults or human negligence, there would be fewer to zero compromises with respect to product quality and higher rate of lot acceptance.

How to build AI defect detection system for Manufacturing?

1. Data gathering

AI is only as good as the data you collect. hence for a well-functioning defect detection system, data collection is paramount. Following are the steps you could follow for visual detection data collection.

Find the right sources (IoT data, camera, historical data, transactional logs, etc).

Automate data collection in real or near-real-time (set up APIs and cloud pipelines for real-time data streaming).

Ensure that there are all types of data – structured, unstructured, and semi (images, categorical and numerical data, x ray or ultrasound images, etc).

There are some data collection best practices you can ensure.

Use real-time sensors and edge computing.

Set up data warehouse or lakehouse to facilitate data processing and storage.

Focus on data traceability, lineage, metadata management, and governance.

2. Data cleaning and preparation

Noisy and unclean data could lead to unreliable predictions. It requires proper clean-up and pre-preprocessing before using that for model training.

Data processing steps to follow for model training

Remove data inconsistencies like duplicates, missing or incorrect values, and other errors.

Standardize data using formatting techniques. Focus on unit conversions, naming structures, categorical encoding, etc.

Feature selection & engineering - remove unnecessary fields or combine them if required.

Label data so it could be easy for the model to learn and pick patterns from data. You can do this manually or using AI-based labelling tools.

When data pre-processing gets difficult, you can try the following steps.

Use synthetic datasets on top of real datasets, when the latter isn’t sufficient.

Use ETL pipelines and automate data processing is the best way to minimize data workloads while building visual detection models.

Apply anomaly detection techniques and detect and remove anomalous values that could cause deviations and bias.

3. Training the model

How well your AI visual detection depends on choosing the right AI/ML approach – there shouldn’t be false positives and defects must be detected accurately. Step by step in training an AI visual detection model

Choose the right algorithm based on datasets you have and results you want. For example, if you have time series data, RNN algorithm can work. Since, visual inspection also includes inspecting images, CNN can also be used.

Splitting data so you could have 70 to 80% of data for training and the rest for training.

Work on hyperparameter tuning to improve model outcomes.

Training the AI visual inspection model is a critical step. For better results, you could run multiple models in parallel and select the best-performing ones or go for pre-trained models.

4. Deployment

We are almost close to automating quality inspection with AI. Deployment is technically the last step to model building. It involves a few technical steps that data scientists will be able to take care of.

Packaging and containerizing the model using docker for simplified deployment.

Use cloud applications like AWS or Azure to deploy and set up real-time processing.

Get APIs up and running so it becomes easy to access everything from users’ end.

Check if the visual inspection system needs to be connected with any existing application.

At last, model versioning to track and follow performance improvements.

Deployment marks the end of the model development, and your AI inspection tool is ready for the real-world environment.

5. Training and evolving

Retraining and model enhancement is to help model adjust to real-world inconsistencies and stay relevant and accurate. You will basically collect feedback, retrain the model, and improve its outcomes.

Collect real-time feedback and use that to improve model’s performance.

Reinforcement learning to detect new anomalous values.

For fewer retraining workloads, could set up auto-retraining pipelines.

There are also many other retraining strategies and techniques like drift detection, shadow modeling, etc., to identify underperforming instances of models and work on them to get desired values. Data scientists should also keep an eye on the following:

What are the false positive and false negative instances (where the detection system identifies a defect when it is not and vice versa).

How explainable are the decisions and how traceable are the results?

What about the compliance requirements? Is the model compliant with the industry standards.

Does the model require observability tools in place to find out any performance drip?

On top of all these, one can go for real-time performance monitoring dashboards that visualize model output vs. Real defect occurrence – much easier to fine tune the model and understand false positives.

Final thoughts

AI for visual inspection isn’t new to the manufacturing sector. In fact, the AI quality inspection market is expected to grow at a CAGR of 28.53% by 2029, reaching close to US$70.747 billion. That shows how AI-based visual quality detection will be more standardized in the coming years similar to demand and time series forecasting. While there are many factors that decide the reliability and accuracy, having qualified data scientists is major, much needed to build custom models, process datasets, train and test them, and evolve it successfully.

Reach out to us if you require the right data science team to build custom AI solutions for your manufacturing business. And turn messy data into a trusted foundation with our data engineering solutions.

FAQs

1. How to use ai for quality inspection?

You can AI for quality inspection once you start collecting data about defects and combine image data with process signals (machine parameters, lot IDs, time, etc). This involves training an AI/ML based model with real defect data, flag anomalies, and build a decision support system based on the outputs generated.

2. Which AI application inspects products for defects on assembly lines?

The AI application that inspects products for defects on assembly lines is called computer vision–based defect detection. It uses high-resolution cameras placed in all angles and transformer or convolution-based models. These systems look for surface defects, assembly errors, or proportional or aesthetic inconsistencies.

3. How manufacturers are using AI to reduce defects?

Manufacturers use AI like predictive models, quality detection systems, and root cause analysis processes to reduce defects. The models link machine settings to defect probability, detection systems flag anomalies, and root cause analysis traces back defects to machines, materials, shifts, and operators. And finally, closed loop feedback where insights adjust process parameters.

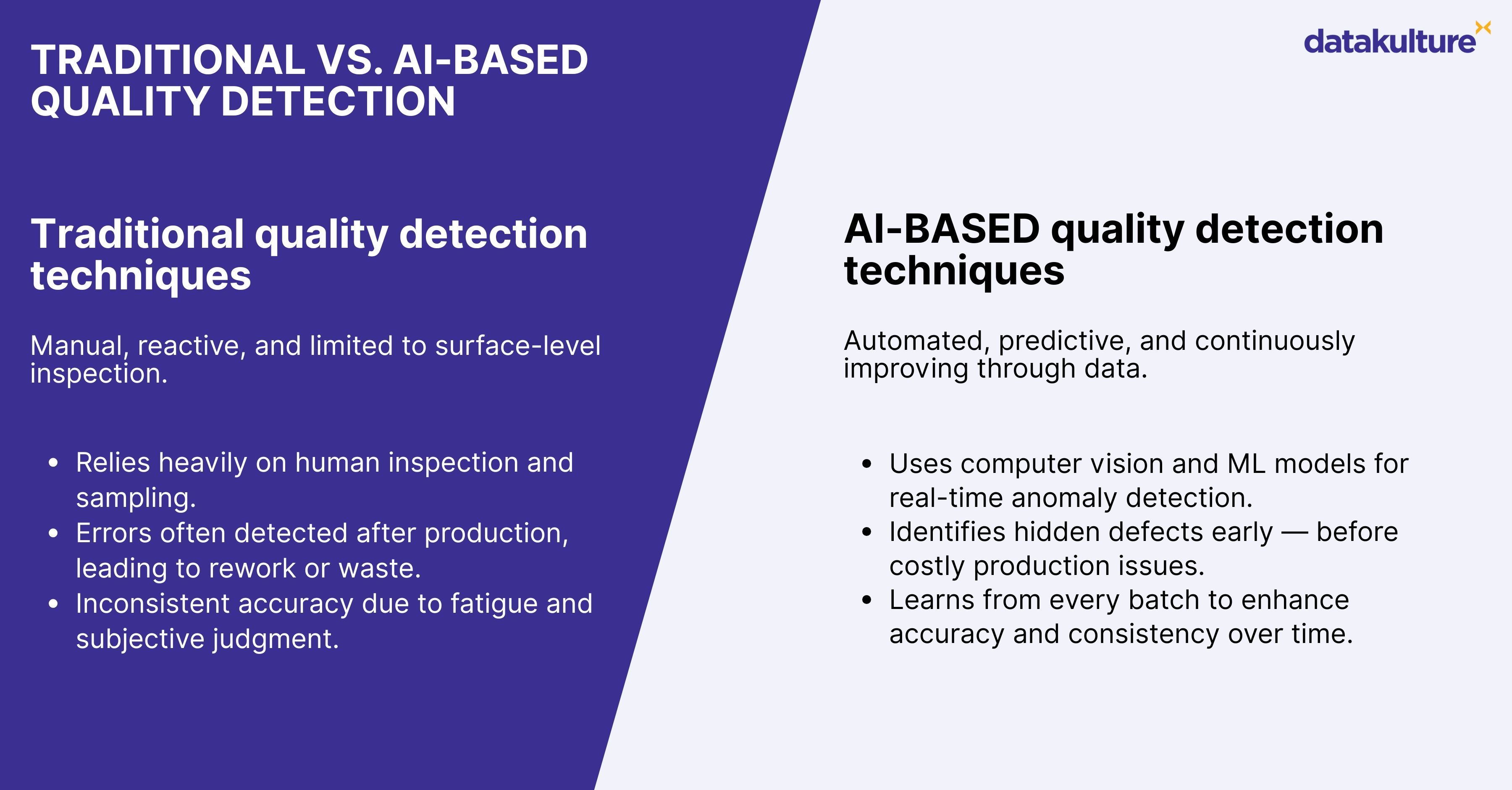

4. Difference between manual and AI-based defect detection?

The difference between manual inspections and AI-based defect detection is that manual inspections are error-prone and time consuming. But AI-based defect detections are automatic and generate more accurate results. It’s much easier to scale with AI-based detection systems rather than employing and managing QC professionals for manual inspections when demand is higher.